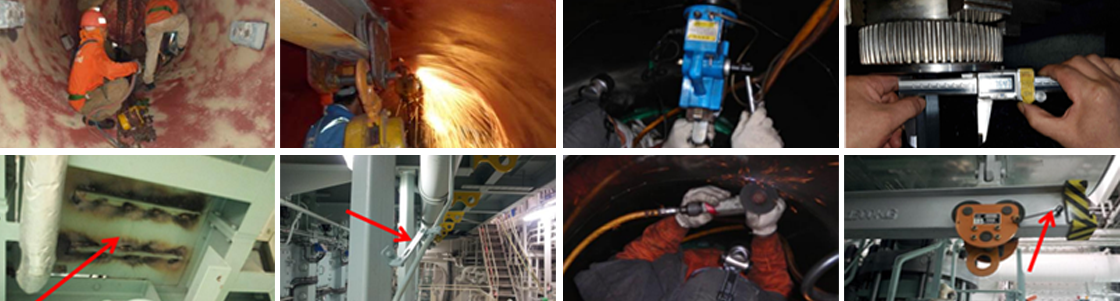

E/R piping modifications, hull repairs & outfitting repairs using ‘Oriental Repair Net-Work’, which covers Singapore, Chinese, Korea ports & GCC and worldwide ports

and all repair quality meets Global standard requirements.

Based on our service experience and our guideline for overhaul intervals, the following parts must be replaced every 5 years or 32,000 R/H to ensure optimal and trouble free operation.

Components Repair kits for VIT Actuator Repair Kits for reversing air cylinder Repair Kits for pneumatic control system Working period : 3 Days in D/D

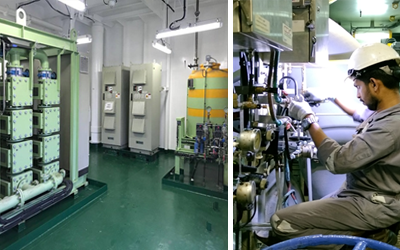

The solution for the damage related to the water content in lube oil system. Installation of Water In Oil Sensor is considered as standard for the future new building projects and retrofit of Water In Oil Sensor for already delivered vessels.

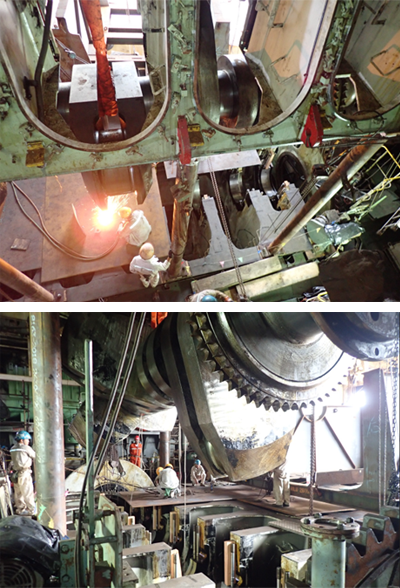

Portable fire extinguisher & CO2 sys service Crane jib cracked plate replacement Cylinder cover overhaul Repair work for windlass M/E top bracing maintenance Crank Shaft Maintenance

ME Type Engine Maintenance

Pneumatic Control Maintenance

Alpha Lubricator Maintenance (5, 10 years)

Maintenance Work / Overhaul inspection according to Engine Running Hour

Overhaul service includes overhaul kit and dispatching S/V at vessel’s dry docking

Correct engine maintenance work for 2,000/4,000/6,000/8,000/16,000 hours will be guided by service engineer during maintenance work

Correct engine operation working procedure will be guided by service engineer during maintenance work in order to protect big damage of engine

High quality maintenance service

Easy of engine operation

Safety voyage

Cylinder head overhaul

Con-rod dis-assembling & maintenance

Main bearing inspection (1 set only)

Piston, liner dis-assembling & maintenance

Timing gear, pump driving gear inspection

Tappet, rocker arm check

Camshaft bearing inspection

Oil pump, water pump inspection

Test trial

Inspection of control unit

Timing check of angle encoder & pick up sensors

Replacement of pick-up sensors

Inspection of feedback sensors

Simulation test by pre-lubrication

Routine maintenance for running hours(5 years, 7 years)

Cylinder lubrication oil saving of 20-50% at low load

More accurate feed rate control at all engine loads

Minimizing over-lubrication at low load, Reducing deposits, hence improving the cylinder condition

lmplementation of latest design features

Upgraded interface by latest software version

The Ballast Water Treatment System (BWTS) is a crucial system for ensuring compliance with environmental regulations, treating ballast water discharged by vessels during voyages to prevent the spread of invasive species and protect the marine ecosystem. However, due to continuous operation and the challenges posed by the marine environment, regular maintenance and repairs are required. We offer specialized repair services for BWTS based on advanced technology and extensive experience.

The Main Engine Pneumatic Control System plays a crucial role in ensuring the efficient operation and safety of the engine. This system is responsible for regulating key functions such as fuel supply, speed control, and automatic regulation. Over time, wear or failures in components can occur, making regular overhauls necessary to prevent issues. We provide specialized overhaul services for the Main Engine Pneumatic Control System to ensure the stable and efficient operation of the vessel.

Ensure safety voyages

Periodic maintenance

Copmonents

- Repair Kits for VIT Actuator

- Repair Kits for reversing air cylinder

- Repair Kits for pneumatic control system

- Working period : 3 Days in D/D

| Interval | Within 1 year | 2 years | 3 years | 6~8 years |

|---|---|---|---|---|

Drain |

Once a day |

Overhaul |

Overhaul Renew rubber part Renew filter elements |

|

Low-Pressure Pneumatic Devioes(less tham 10kgf/cm2) |

Overhaul |

Overhal Renew rubber part Renew filter elements |

||

Low-Pressure Pneumatic Devioes(less tham 30kgf/cm2 or less) |

Overhal |

Overhal Renew rubber part Renew filter elements |

Ship machinery parts can gradually wear out or fail due to various external and internal factors during operation. To keep these machinery components in optimal condition, regular repairs and overhauls are essential. We offer comprehensive repair and precision overhaul services for ship machinery parts, providing professional support to optimize vessel performance and minimize operational downtime.

Repair and overhaul work related to machinery parts plays a vital role in ensuring the safe and efficient operation of the vessel. Our key services include: